OEM Project Stories

Customized Hardware

Since most of the industries in Taiwan are small to medium enterprises, almost all the production processes are proceeded by different individual process contractors. Therefore, the success of customized hardware manufacturing depends on whether the company that provides the OEM services has the coordination and integration capabilities and experience.

Normally, the Molds are generated by molding contractors; other processes whatever the CNC, Die Casting, Forging, Stamping, Injection, Pressing, Painting, Plating, Anodizing ... or even the Polishing, all of such specific processes are preceded by different contractors. They focus on the process of what they do only; they do not know other processes.

Therefore, if you are seeking a factory for your existing product or new development project who can responsible for the total quality assurance from the beginning till the end (packing and delivering), please feeling free to contact us, we are capable to evaluate and give the comments, no matter on material, design or dimension and the life test. Our engineering team is very experienced in how to handle and develop for you, their knowledge in manufacturing processes and the assurance in quality control will satisfy you.

Below are some of the OEM projects which we handled before,

Project #1 Luxury Brands’ Gift Boxes

For this project, we started with the SAMPLES, our engineers drew the logo and drawings by themselves, and then they started producing the prototype later on. Although it looks simple, the specific color which our customer requests are very unique and details that all of the parts should be the same, so the technique and proceeding control of aluminum anodizing is very important. Also, they care about the quality of it; even one small spot is not acceptable. Therefore, we gained the experience of the well-controlled quality from this luxury brand project.

**Process Involved:

Extrusion-aluminum / CNC lathe / Stamping / Threading tapping / Laser carve / Polishing / Anodizing / Fasteners / Coil springs / Assembling / Packing

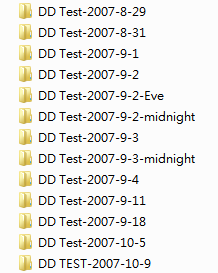

Project #2 Touch’n Hold Storm door closer development

This is a very knowledgeable and educated project, we learned a lot whatever the designing, production, packaging, and especially the development and testing from this project as the products are supplied to the American biggest door manufacturers.

The product design principles by creating the vacuum negative pressure generated in the cylinder, to balance the strong force of the spring in the initial stage of rebound, provide a more uniform speed while the door is closing; avoid hurting or hitting the people.

But the spring force is not a fixed number, it will increase or decrease by compression or relaxation. For example,

How much vacuum negative pressure should we create?

In which position is the negative pressure sufficient to offset the force of the spring when it is in position?

Where will the negative pressure be consumed?

Where can the usual exhaust valve be used to control the final closing speed?

...

All of the above questions are just a couple of examples of what has been repeated thousands of times by us, repeating assumptions, speculations, testing and then revising, revising, and testing, ... and finally the most perfect design version is finalized.

**Process Involved:

Co-development / Plastic Injection / Plastic welding / Plastic lathe / Rubber Compression molding / Metal Stamping / Fasteners / Springs / Non-Woven Fabric / Assembling / Various blister-board packing / Various testing under high & low temperatures, compression, maximum pulling, dropping, cycles, force, bending,...

Project #3 TRUTH Sliding door handle sets

For this project, the process and components come from 12 different sub-contractors; therefore, the coordination, integration capabilities, and experience are indeed important.

It also means our good quality control ability on each process. We feel very fortunate and proud with this opportunity to be an OEM for this Europe and the United States well-known hardware brand, trained and led our manufacturing and quality control capabilities reached world-class standards.

**Process Involved:

Forging Brass / Die-Casting / Plastic Injection / Metal Stamping / Polishing / Fasteners / Lock cylinders / Foam gasket / Styrofoam / Plating & Powder Coating / Assembling / Packing

Project #4 Digital safe boxes’ gear motor and electrical connecting

Metal and plastic processing is already our area of expertise, which is definitely not a problem for us. We conducted further training on the circuit connection and inspection of this project. Thanks for giving us this opportunity to further develop into different industries.

**Process Involved:

CNC turning /Plastic Injection / Die-Casting / Circuit Connection / Assembling / Packing

Project #5 AluminART Storm door handle lock set

Metal processing is also already our area of expertise, which is definitely not a problem for us, too.

**Process Involved:

Die-Casting / Plastic Injection / Metal Stamping / Plating Finish / Assembling / Packing

Project #6 Lexus automobiles parts

Metal processing is already our area of expertise, which is definitely not a problem for us. Furthermore, we are excited about the opportunity to get involved in the automobile industry.

**Process Involved:

Metal Stamping / Packing

Project #7 Cable tie down for pool and screen enclosures

Metal processing is already our area of expertise; we didn’t know where the CABLE TIE DOWN was to be used while we were producing for the customers. Anyhow, it is absolutely not a problem for us...

**Process Involved:

Metal Stamping / Metal Cable / Powder Coating / Aluminum anodizing / Assembling / Packing

Other OEM projects examples:

**Process Involved:

Stainless steel lost wax casting /Metal Stamping / CNC lathe / Die-Casting / Powder Coating / Aluminum anodizing / Plating / Assembling / Packing…

.jpg?v=d557742d)

.jpg?v=b29f329a)

.jpg?v=0053dde0)

.JPG?v=b9d276d1)

.jpg?v=096fc016)

.JPG?v=af270e3b)

.jpg?v=bb06ce98)

.jpg?v=48915efe)

.jpg?v=1480e206)

.JPG?v=fa51a12a)

.jpg?v=1b89ad74)

.jpg?v=67ba05fe)

.JPG?v=f143fbd5)

.JPG?v=5186bc6f)

.jpg?v=1fc5e386)

.jpg?v=09db7b04)

.jpg?v=52b3b6ca)

.jpg?v=f2f8ace7)

.jpg?v=60aa34ef)